Mencari

Tren Masa Depan Kendaraan Energi Baru Global dan Meningkatnya Permintaan Pompa Sirkulasi Pendingin

Seiring dengan percepatan transisi dunia menuju solusi energi yang lebih bersih dan berkelanjutan, kendaraan energi baru (NEV) telah muncul sebagai salah satu teknologi paling menjanjikan untuk mengurangi emisi karbon. Maraknya kendaraan listrik (EV) dan kendaraan hibrida mengubah industri otomotif global, dengan dampak signifikan terhadap berbagai komponen, termasuk pompa sirkulasi cairan pendingin. Blog ini mengeksplorasi tren masa depan NEV, meningkatnya permintaan akan pompa sirkulasi pendingin, dan distribusi basis produksi serta keunggulan teknologi dari pompa ini.

Kendaraan energi baru, yang terutama mencakup kendaraan listrik (EV), kendaraan hibrida (HEV), dan kendaraan hibrida plug-in (PHEV), mengalami pertumbuhan pesat secara global. Menurut laporan industri, pasar kendaraan listrik global diperkirakan akan mencapai hampir 40 juta unit pada tahun 2040, dan kendaraan listrik menyumbang lebih dari 50% penjualan mobil global pada tahun 2035. Pergeseran ini didorong oleh insentif pemerintah, peraturan emisi yang lebih ketat, dan peningkatan jumlah konsumen. permintaan akan pilihan transportasi yang lebih ramah lingkungan dan hemat energi.

Selain peningkatan penggunaan kendaraan listrik, pasar kendaraan sel bahan bakar hidrogen (FCV) dan kendaraan listrik otonom juga berkembang. Kemajuan ini didorong oleh inovasi dalam teknologi baterai, infrastruktur pengisian daya, dan desain kendaraan. Hasilnya, industri otomotif menyaksikan transformasi signifikan menuju solusi transportasi yang lebih berkelanjutan dan efisien.

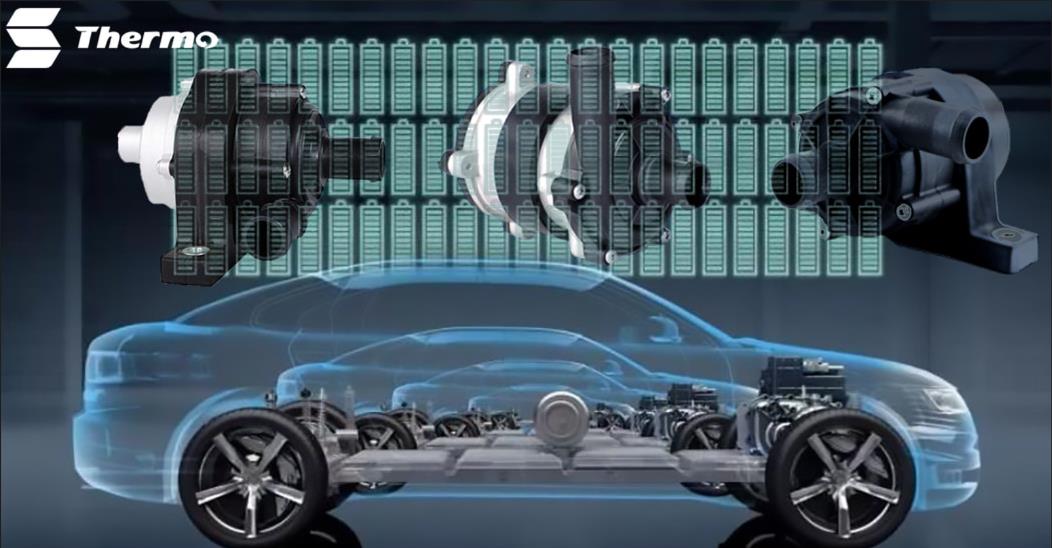

Dengan munculnya NEV, permintaan akan pompa sirkulasi pendingin juga sedang meningkat. Pompa ini berperan penting dalam menjaga suhu pengoperasian optimal untuk sistem kendaraan listrik dan hibrida, termasuk baterai, elektronika daya, dan motor listrik. Manajemen termal yang efisien sangat penting untuk memastikan keamanan, kinerja, dan umur panjang komponen-komponen ini.

Pada kendaraan mesin pembakaran internal (ICE) tradisional, mesin itu sendiri menghasilkan panas yang dikelola melalui sistem pendingin cair. Sebaliknya, NEV memerlukan solusi pendinginan canggih untuk paket baterai bertegangan tinggi, inverter, dan komponen listrik lainnya, yang beroperasi pada suhu jauh lebih tinggi. Oleh karena itu, permintaan yang tinggi adalah pompa sirkulasi cairan pendingin yang dapat memberikan kontrol suhu yang tepat dan menjaga efisiensi sistem ini.

Selain itu, semakin populernya kendaraan listrik dengan kemampuan performa lebih tinggi, seperti kendaraan listrik dengan pengisian cepat, telah meningkatkan kebutuhan akan solusi pendinginan yang lebih efisien. Pompa sirkulasi cairan pendingin membantu mengatur panas yang dihasilkan selama pengisian dan pengosongan cepat, memastikan baterai beroperasi dalam batas suhu yang aman.

Meningkatnya permintaan akan pompa pendingin mobil telah mendorong kemajuan teknologi yang signifikan dalam desain dan manufaktur pompa. Pompa pendingin modern untuk NEV lebih hemat energi, tahan lama, dan kompak dibandingkan pompa tradisional. Keunggulan teknologi utama meliputi:

1. Teknologi Motor DC Tanpa Sikat: Pompa sirkulasi pendingin untuk NEV sering kali menggunakan motor DC tanpa sikat (BLDC), yang menawarkan efisiensi lebih tinggi, pengoperasian lebih senyap, dan masa pakai lebih lama dibandingkan motor sikat tradisional. Motor BLDC juga lebih hemat energi, sehingga mengurangi konsumsi daya keseluruhan sistem pendingin kendaraan.

2. Sistem Kontrol Cerdas: Banyak pompa pendingin modern dilengkapi dengan sistem kontrol canggih yang memungkinkan pemantauan suhu dan laju aliran secara real-time. Sistem ini memastikan pompa beroperasi secara optimal, menyesuaikan aliran cairan pendingin berdasarkan fluktuasi suhu untuk menjaga kinerja yang konsisten.

3. Desain Kompak dan Ringan: Karena ruang dan berat menjadi faktor penting dalam desain kendaraan listrik, pompa sirkulasi cairan pendingin menjadi lebih kompak dan ringan. Pompa ini dirancang agar sesuai dengan ruang sempit di dalam kendaraan dengan tetap mempertahankan standar kinerja tinggi.

4. Bahan Tahan Korosi: Pompa sirkulasi cairan pendingin yang digunakan pada kendaraan listrik sering kali dibuat dari bahan tahan korosi untuk memastikan daya tahan dan kinerja jangka panjang, bahkan dalam kondisi pengoperasian yang sulit.

5. Ketahanan Suhu Tinggi: Ketika kendaraan listrik terus mendorong batas kinerjanya, pompa pendingin dirancang untuk menangani suhu yang lebih tinggi, memastikan bahwa baterai dan perangkat elektronik daya tetap dingin di bawah beban berat.

Peralihan global menuju kendaraan energi baru mengubah industri otomotif, dan seiring dengan itu, permintaan akan solusi pendinginan yang efisien seperti pompa sirkulasi cairan pendingin. Ketika kendaraan listrik dan kendaraan hibrida menjadi lebih umum, kebutuhan akan pompa yang canggih dan hemat energi akan terus meningkat. Produsen merespons dengan teknologi mutakhir yang menawarkan peningkatan kinerja, keandalan, dan efisiensi energi, memastikan bahwa pompa sirkulasi cairan pendingin memainkan peran penting dalam keberhasilan NEV di seluruh dunia.

Seiring dengan meningkatnya permintaan akan kendaraan energi baru, produksi global pompa sirkulasi cairan pendingin siap untuk diperluas, dengan pusat-pusat manufaktur utama di Tiongkok, Eropa, dan Amerika Utara mendorong inovasi dan memenuhi kebutuhan pasar yang terus berkembang.